REASONS TO INVEST IN AN ANNUAL ELECTRICAL SAFETY INSPECTION FOR YOUR HOME OR BUSINESS

In an ideal world, every time you go to flip a light switch or plug in an electronic device, you are going to get a steady, safe stream of power, but sadly, that isn’t always the case. Your electrical system is a massively complex organism, and from time to time, it develops little hiccups that can inhibit it from performing like it should.

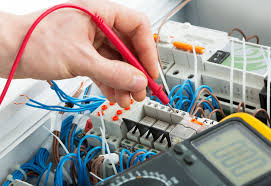

When it comes to keeping your home or business’s electrical system functioning like it should, one of the best things you can do is call in a professional electrician and have them perform a thorough electrical safety inspection on your system. There are a number of different reasons that come together to make getting an electrical safety inspection a wise investment for your home or business, and to highlight exactly what a few of those are, our team of professional electricians have taken the time to put together this short list identifying exactly what a few of those are.

Fire Safety

Because we make use of it so frequently on a daily basis, it is easy to forget sometimes just how dangerous electricity can be. One of the major threats that can arise from an electrical system that isn’t operating correctly is the risk of fire. Faulty or outdated wiring is one of the leading causes of home and business fires all over the country, but taking the time to get an annual electrical safety inspection for your property can help resolve these issues before they have a chance to become a threat. During your inspection, our team of professionals will go over your system thoroughly and make sure all of your wiring is up to date and up to code, as well as resolve any lingering issues that could become a safety hazard given the right conditions.

Personal Safety

While faulty electrical systems definitely put your property at an increased risk of fire, they can also create shock hazards for you, your family, employees, or customers. Whether it is from electrical overloading, faulty outlets, wiring, or whatever the case may be, it is important to catch these issues before someone gets hurt. With an annual electrical safety inspection, you can have our team of professionals go through your system and catch any of these hazards before anyone gets hurt. Helping to protect those important to you and improve the overall safety of your property.

Adherence To Electrical Code

When it comes to your electrical system, whether in your home or business, it is important to ensure that everything is operating correctly and is in adherence with all local electrical codes. If it has been some time since your electrical system was updated, or you have had any work done to your system by a less-than-professional technician in the past, electrical safety inspections can be a great way to not only ensure your system is operating safely, but to ensure every aspect of your electrical system is in compliance with these electrical codes.

Electrical Home Inspection and Safety Check

Are you buying or selling a property? Are you renting out a property and want to make sure it is safe? An Electrical Home inspection and safety check can prevent any serious electrical accidents from occurring in the future. Most house fires are caused by faulty wiring, overloaded circuits or faulty appliances. Surprisingly though most homeowners do not bother to have their home checked until something goes wrong, like a loss of power or tripping circuit.

When should you have an electrical home inspection and safety check done?

If you are buying or selling a property

If you have not had an electrical home inspection done before or it has been more than 5 years

If your home is more than 20 years old

No damage is caused to your system due to improper handling

What is involved in an electrical home and safety check?

The qualified licensed electrician will first do a visual inspection of the electrical wiring, power points and switches

The electrician will then run some detailed tests with the power off. Including testing circuits and power points

Testing and tagging of appliances if required. Read more about test and tag requirements here

Using a checklist, the electrician will list all items inspected and their condition. (Good, Fair or poor)

What will you receive?

On completion of the inspection, you will then receive a detailed report outlining any potential electrical hazards and recommendations. These may include:

Broken power points, lights and switches

Old broken wiring

A lack of earthing or bonding

Overloaded circuits

Old broken fuses/lack of safety switches

Dangerous or DIY electrical work

Home Electrical Safety Challenge

Why is there a different kind of outlet in my bathroom? What does that “TEST” button do? Why does the circuit breaker trip every time my portable air conditioner comes on? What’s the difference between a power strip and a surge protector?

Do you know everything you should about your home’s electrical system and the electrical products you use in it every day? If you’re like most people, the answer is probably “no.” It’s time to change that.

Electrically-related home fires and incidents result in hundreds of deaths, thousands of injuries and more than a billion dollars in property damage each year. A healthy respect for electricity and a basic knowledge of electrical safety practices can help keep your home and family safe from electrical hazards all year long.

The Home Electrical Safety Challenge provides a simple exercise to help you give your home an electrical safety “check-up.” Each week during National Electrical Safety Month, use the Challenge worksheets in this section to take a look at a different area of your home. Learn to identify potential electrical hazards and correct them. Making a few easy changes to improve safety can also lead to increased energy efficiency and savings on your utility bills.

Is your home ready for the challenge?

The Home Electrical Safety Challenge was developed to help raise awareness about potential home electrical hazards. This exercise is not a substitute for an electrical system inspection performed by a licensed, qualified electrician.

Electrical Safety Inspection

Whether you have an old home, new home, or are doing renovations, you need to get an electrical safety inspection. It is recommended that you have at minimum annual safety inspections to keep your home or business safer.

Electrical Panel Inspections

The Circuit Breaker Panel is the main control box for electricity in your entire house. If left unattended, and wires come lose or break, you could end up with a serious problem, even an electrical fire. An annual inspection of your breaker box allows your electrician to check for loose wires, proper breaker connections, and identify any hot spots that pose a threat to the breakers or connections.

Smoke & Carbon Monoxide Detectors Inspection

Smoke and Carbon Monoxide Detectors save lives once they are maintained properly. This means testing that the detectors work monthly, changing the batteries yearly, and scheduling annual inspections with your licensed electrician.

Arc-Fault Protection

An arc-fault is where you have a high-powered electricity discharge that translates into heat and has the possibility of damaging the wire’s insulation. When this happens, there is the possibility of it causing an electrical fire. This could be from plugs that are pulled slightly loose which cause arching.

Inspecting Your GFCI Outlets

The Ground Fault Circuit Interrupter (GFCI) is designed to protect you from electric shock in places where there may be water. This is why GFCI outlets are ideal for outdoors, bathrooms, kitchen counters, pool areas, etc. Similar to the AFCI devices, your GFCI outlets should be tested monthly using the test button on the outlet. And they should be inspected at least annually by a professional electrician.

ELECTRICAL SAFETY INSPECTION CHECKLIST

Outlets and Light Switches

Work your way through the home and make note of any outlets or light switches that aren’t working. When an outlet or switch fails, it may be a sign that the wiring behind it is faulty.

If you touch the outlet or switch, is it warm or hot? This is also a sign that the wiring could be faulty.

Whenever the outlet or switch components appear to have changed color to look burnt or brown, don’t use them.

If you hear them making any noises, such as a buzzing sound, the wiring is probably loose.

Are the outlets or switches loose? This is a potential hazard that can lead to overheating and eventually cause a fire.

Electrical Cords

Are the cords in good condition?

Do the cords run unobstructed by furniture or other objects?

Have you removed any staples or nails that compress the cords?

Do cords run around or on top of carpets, not underneath them?

Do you use extension cords sparingly?

Do all cords run in a straight line, without purposefully wrapping?

If you can answer yes to these questions, your electrical cords are in good shape. If you answered no to any of these questions, change your practices around the home. Pinched, stapled or nailed cords can lead to damage, overheating and fire hazards.

Appliances, Lighting and Circuits

Operate your lights and lamps safely by checking the wattage of the bulbs. Never install a bulb with a wattage that’s higher than the recommended use.

Check the appliances in your kitchen. Make sure that the cord to your coffee maker, for instance, isn’t close to the stove, where exposure to heat is possible.

Take note of the number of times electrical breakers have tripped. Tripped breakers or blown fuses can be signs of an overextended electrical circuit.